Materials & Applications

Wet paint & Powder Paint

A full range of performance coatings are available to you and Cove can assist in choosing a suitable material for your application.

Cove devote a great deal of attention to pretreatment and masking operations understanding that the final finish is dependant upon good adhesion to the substrate. Once these stages are complete the work is released for final finishing using suitably selected or special customer specified materials from a range of performance coatings.

Powder coating

An extremely attractive, durable, scratch resistant, chemical resistant, and UV resistant coating. Epoxies exhibit good mechanical properties but poor UV resistance. Urethanes and polyesters exhibit excellent UV and weather ability. Cove can assist in helping you choose the best material for your application.

Wet paint

Include stoving and, where post application heating is not possible, two pack systems. Spatter finish and many other texture effects are also available to you in a limitless number of colours.

Aerospace and defence coatings

Cove is quickly establishing itself as a market leader in Aerospace and Defence finishing

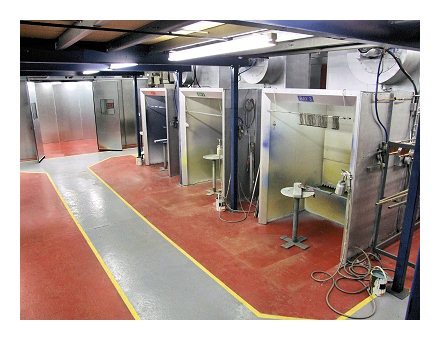

For all your Aerospace and Defence painting needs look no further than Cove paintshop. Utilising our state of the art facility we are quickly establishing ourselves as market leaders in the Aerospace and Defence supply sector, we have developed a reputation for the supply of high quality painted parts using paint obtained from some of the biggest suppliers such as Trimite, Silmid, Mapaero, Mankiewicz, Hempel and PPG aerospace.

We offer a range of coatings including 3M EC3960 Primer, 2 Pack Epoxides and 2 Pack Polyurethane paints from small batch work through to large quantities all taken care of by our dedicated and highly skilled staff.

With a brand new environmentally compliant pre treatment plant, precision masking service and dedicated clean room facility there really is no need to look any where other than Cove.

ATM Refurbishment

Cove’s standard of work has allowed the develpoment of an extended service dedicated to the exacting standards requried for ATM refurbishment.

The final stage of ATM refurbishment prior to reassembly requires the complete refinishing of the component parts of the machine internally and externally. This is an exacting process requiring the selection of superior materials and skill of application to meet, and in some cases, exceed the original requirements of the manufacturer.

ATM machines are constructed from a variety of plastics and metals that each require specific procedures for both preparation and final finishing. As would be expected, an ATM machine can see a great deal of abuse and wear during its life time and this is especially so in the case of the exposed cosmetic parts such as fascia’s etc

Exceptional skill and attention to detail is required to bring the machines back to up to the standard of new and Cove’s expertise ensures that these standards are met or exceeded.

Accurate colour matching is of course standard and Cove can apply materials in colours to suit your own custom branding.