Equipment & Pretreatment

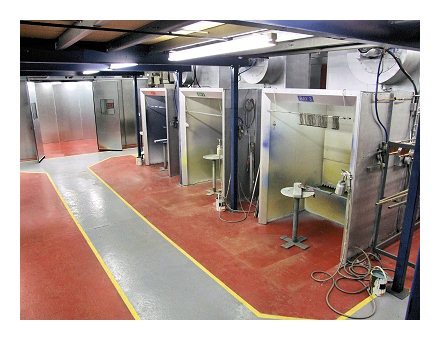

A dedicated and well equiped paint shop compliment Cove’s sheet metal facilities

Clean Room

Fully sealed and filtered wet spray booth with a maximum part size of 3 metres long 2 metres wide and 1 metre high

Cove’s Clean room is built around an RDM fully sealed and filtered spray booth water extraction system. Designed to remove Toxic Fumes, Paint and Powder dust from spray shops ensuring healthy and suitable working conditions and compliance with inspectorate requirements. A water scrubbing tower is used to prevent particles being exhausted to atmosphere.

Phoswash

Aqueous pre-treatment phosphating plant

At Cove Industrial Enterprises Ltd we are constantly seeking ways to improve our operations and stay one-step ahead in the sheet metal fabrication and paint industry.

With the usage of solvent based pre-treatments (such as Trichloroethylene) now limited to 1 ton per year (and with expectations that this will be further reduced in the future), there is rapid growth in the demand for environmentally friendly alternatives

As part of our major expansion and modernising program over the last few months, we have now installed the latest Aqueous degreasing cleaning system from Vixen Surface Treatments. This means we have future proofed this vital stage of the paint process, ensuring the services we provide are not affected by the above restrictions.

Def Stan 03-11

Not only does the Vixen machine have a larger capacity than its solvent predecessor, the machine also provides us with the capability to supply Phosphate coating to Defence Standard 03-11 (we are one of only a handful of companies in the South currently offering this process). This compliments our full range of high quality wet and powder paint finishes, which also meet the Aerospace and Defence industries exacting standards.

AQUEOUS DEGREASING

Provides a wash, rinse and warm air flash drying facility, avoiding drip drying and ultimately saving time for a quicker turn-around from fabrication to completed paint finish.

PHOSPHATE COATING

In addition to the stage 2 processes the stage 3 phosphate coating process provides enhanced corrosion resistance for steel. It also provides excellent paint adhesion, whilst eliminating the need for etch prime processes.

We take great pride in providing a fast efficient service whilst maintaining the highest levels of quality

With our team of highly skilled and professional staff we are proud to offer an excellent powder coating and wet spraying service to our expanding customer base.

We take great pride in providing a fast efficient service whilst maintaining the highest levels of quality utilising the most up to date and efficient paint spraying and surface treatment equipment and machinery such as:

- Vixen Phoswash degreasing and surface treatment machine

- Mindon Engineering 4 metre box oven

- RDM fully sealed and filtered wet spray booth with a maximum part size of 3 metres long 2 metres wide and 1 metre high

- 3 x Binks-Bullows wet and powder spray booths

- Ballard automated conveying oven.