Your trusted outsourced partner

At Cove, we work alongside our customers in engineering-led industries and pride ourselves on being an extension of your team for custom- metalwork engineering and electro-mechanical integration. We understand you want to focus on your core strengths and be confident your non-core, yet intricate, projects have been entrusted to experts in their field.

That is why we own every step of the process, providing you a single point of contact, improving your customer experience and protecting your brand reputation at every stage. Our customers outsource complex projects to Cove because they trust us to get the job done.

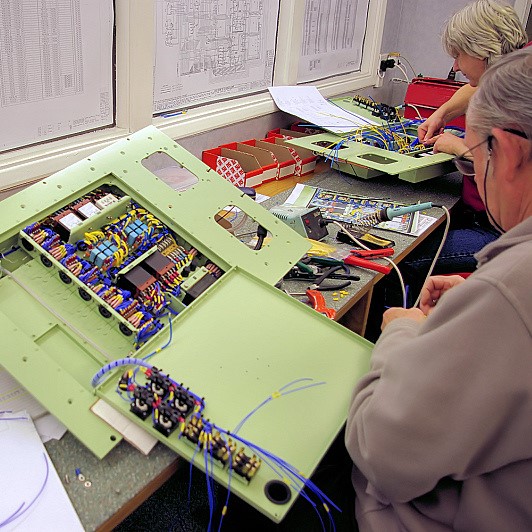

Electro-mechanical integration

Our end-to-end capabilities provide continuity across the whole picture, simplifying the process for everyone involved . For projects requiring a complete solution, our comprehensive build to print service includes precision metalwork engineering, paint finishing and electro-mechanical integration.

Precision metalwork

engineering

For customers integrating hardware in-house, we engineer custom integration-ready metalwork complete with paint finishing. We are well-versed in meeting demanding specifications, providing our customers with the capabilities that enable their designs to be realised.

Electro-mechanical integration

We have decades of experience in the development and manufacturing cycle of electronic products and systems, with projects spanning from small brackets through to large assemblies and equipment racks for military, marine and aerospace applications. Our services include build to print, box building and custom cabling. We also offer value added design support to our customers during initial project to reduce development cycles significantly.

Precision metal engineering

We manufacture metalwork and rack systems to meet the exact requirements of the aerospace and defence industries, with our services including welding, milling, turning, assembly and both CNC folding and punching. Whether you need prototypes or full production runs, you can count on our highly skilled team to provide you with a first-class product. We have the skills and technology to manufacture a range of precision metalwork, including racks, shielded enclosures and portable component housings to suit high heat, chemical and EMC environments.

Paint shop

Our paint shop is an important component of our fully comprehensive precision metal engineering service. High performance, compliant materials coupled with our experience in applications across multiple sectors assures an exceptional finish. To ensure the best finish, we lend customers our extensive expertise, recommending the best paint and powders and how best to apply them. Our services including aqueous pre-treatment, phosphate coating, wet and power painting, silkscreen and pad printing and both laser and mechanical engraving.

Our team is on-hand to deliver quality standards on a large scale with improved speed to fulfilment and great value. Our manufacturing know-how and innovative processes mean we never compromise on quality. Give us your design and we will realise the manufacturing to the scale you need.

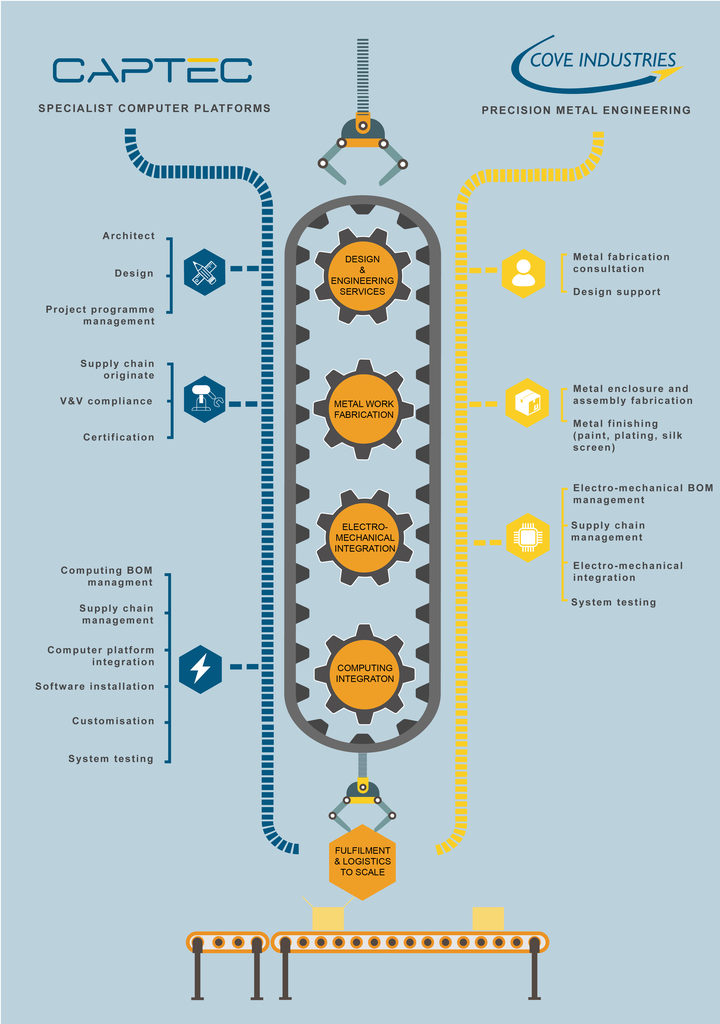

Complex processes simplified

The skill and expertise required to realise the design and coordination of all moving parts in the specialist metal and integration process is often underestimated or taken for granted.

With support from our parent company, Captec Group, we are able to engineer a complete solution, designed to print and tailored to your needs. With a consolidated supply chain, we remove the headache of managing multiple providers and leave you to focus your resources where they matter most.

Why Cove?

57 years’

experience

With an experienced team of experts and a reputation for quality and dynamism, Cove represents a tried, tested and trusted brand in precision metalwork manufacturing and electro-mechanical integration.

Part of a financially robust Group

We are moving forward with confidence. The backing of a financially robust parent group company enables us to scale orders from tens to thousands of units.

For manufacturing industries, this new capability creates a single point of contact and a streamlined supply chain.

Advanced machining and integration facilities

We have heavily invested in CNC forming equipment, paint application and curing equipment, enabling the most demanding formed and finished sheet metal requirements to be fulfilled with ease.

Our electro-mechanical integration facility is fully ESD protected for electronic systems and is overseen by our ISO9001 quality management system.

Cove are part of the Captec Group. For more information on the Captec Group visit Captec-Group.com